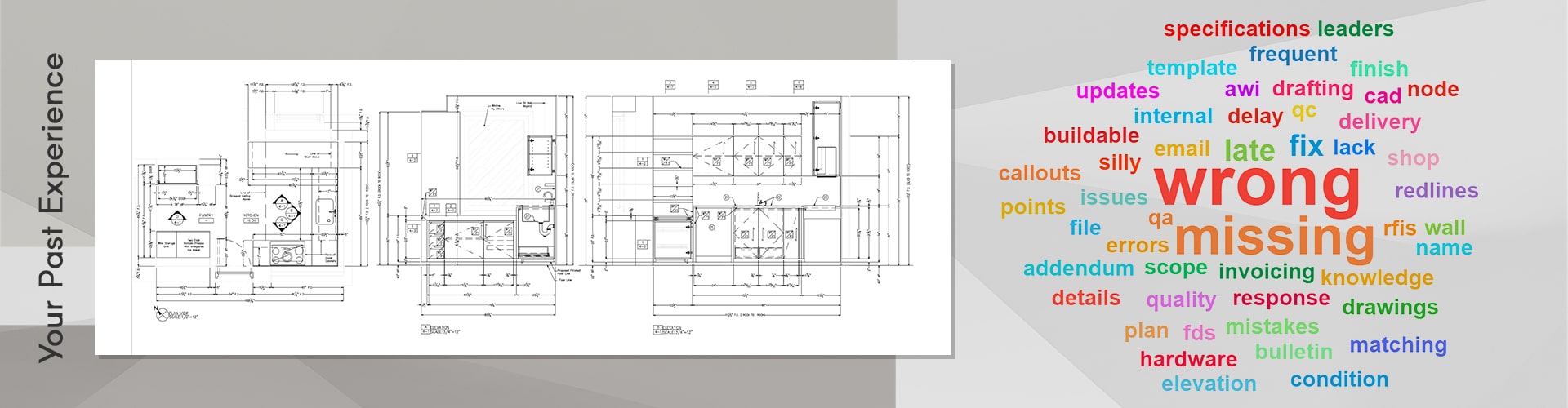

Millworkers often face significant challenges when working with external DRAFTING VENDORS, especially if those vendors aren't deeply familiar with the practical side of Millwork Fabrication.

Example: A vendor shows a 1/4" solid wood face frame joint with no allowance for seasonal expansion or glue strength.

A cabinet interferes with a electrical panel not shown in the architectural file.

Drafting based solely on architectural drawings, without real-world verification.

The shop spends extra hours just cleaning the drawings to make them usable.

Reusing details or blocks from previous jobs without adjusting to new specs.

Millworkers waste time clarifying details that should've been resolved in the drawing set.

Delay in submitting within the agreed timeline.

Invoices sent after expected billing cycle.

Unresponsive or slow communication impacting Project flow.

Millwork Scopes not included in the deliverables.

Drawings are sent without proper Quality checks.

Architect Markups or Corrections not incorporated.

Field Dimensions not incorporated.

Scopes not reflecting as per Bulletins/Addendums in the drawings.

Wrong Equipment/ Plumbing Specification.

CAD files are not named as per Standards.

Wrong Finish Tag.

Hardware type, model, or location does not match Project Hardware Specs.

Inconsistencies between Plans and Elevation views.

Arch. Scan References missing in the drawings.

Incorrect wall types or conditions shown in drawings.

Leader lines are misaligned or not pointing to the correct element.

Node points are not accurately placed, causing alignment issues.

Millworkers want Precise, Buildable, and Coordinated Drawings that:

For all these problems, ARCHMAYA is the one Stop Solution.